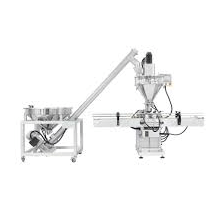

Who Provides the Best Filling Machine in China?

In the fast-paced world of manufacturing and packaging, finding the right filling machine can be a game-changer for businesses. China has emerged as a powerhouse in the manufacturing industry, and when it comes to filling machines, there are several key players competing to offer the best solutions. In this article, we’ll delve into the top providers of filling machines in China, exploring their offerings, innovations, and the factors that set them apart.

1. Introduction

Eye Drop Filling Machines play a pivotal role in modern manufacturing, ensuring that products are efficiently and accurately dispensed into containers. From liquids to powders, these machines have revolutionized the packaging process, enhancing productivity and reducing manual labor. As businesses in China strive for excellence in production, the quest for the best filling machine has become a crucial decision.

2. The Importance of Filling Machines in Manufacturing

In the dynamic landscape of manufacturing, speed, and precision are paramount. Filling machines enable manufacturers to maintain a consistent and controlled flow of materials into containers, minimizing wastage and ensuring each product meets the desired standards. Whether it’s the pharmaceutical, food, and beverage, or cosmetics industry, filling machines have a significant impact on product quality and operational efficiency.

3. Top Providers of Filling Machines in China

Innovative Machines Co.

Innovative Machines Co. has carved a niche for itself by offering cutting-edge filling solutions. With a focus on technological advancements, they provide a wide range of machines suitable for various industries. Their commitment to innovation and quality has earned them a reputation as one of the leading filling machine providers in China.

SinoFills Engineering

SinoFills Engineering boasts a diverse portfolio of filling machines that cater to different production needs. Their attention to detail and precision engineering make them a reliable choice for businesses seeking top-notch filling solutions. Whether it’s semi-automatic or fully automated systems, SinoFills Engineering has gained recognition for their commitment to excellence.

EastTech Machinery

EastTech Machinery stands out for its emphasis on customization. They understand that different industries have unique requirements, and their team works closely with clients to tailor-fill solutions to their specific needs. This customer-centric approach, coupled with their expertise, has made EastTech Machinery a reputable player in the market.

PreciseFill Technologies

As the name suggests, PreciseFill Technologies focuses on accuracy. Their filling machines are designed to deliver precise measurements, ensuring that each product is filled to perfection. This level of precision is particularly crucial in industries where even the slightest variation can impact product quality and consumer satisfaction.

NextGen Fillers

NextGen Fillers may be a newer entrant, but they’ve quickly gained attention for their innovative approach. They leverage the latest technologies, such as IoT integration and real-time monitoring, to provide a holistic filling experience. Their willingness to push boundaries and explore new avenues sets them apart in the competitive landscape.

4. Key Features to Consider

Choosing the best filling machine involves a careful evaluation of various features that align with your production requirements. Here are some key aspects to consider:

Production Capacity

Depending on your production volume, you’ll need a filling machine that can keep up with demand. Whether it’s a high-speed continuous filler or a compact machine for smaller batches, selecting the right capacity is crucial.

Versatility and Customization

Industries evolve, and so do their needs. Opt for a filling machine that offers versatility and can adapt to different types of products and containers. Customization options allow you to fine-tune the machine according to your changing requirements.

Automation and Integration

Automation streamlines the production process, reducing the need for manual intervention. Look for machines that seamlessly integrate with your existing production line and offer user-friendly interfaces for easy operation.

Accuracy and Precision

For industries where exact measurements are essential, accuracy is non-negotiable. Invest in a filling machine that can consistently deliver precise fills, ensuring uniform product quality.

5. Factors Influencing the Choice of Filling Machines

Industry-Specific Requirements

Different industries have unique demands. Consider factors such as viscosity of the product, container type, and hygiene standards to ensure the chosen filling machine aligns with your industry’s specific needs.

Budget and Cost Considerations

Investing in a filling machine is a significant decision. Evaluate your budget and calculate the long-term benefits to make an informed choice that provides value for money.

After-Sales Support and Maintenance

Smooth operations rely on ongoing support and maintenance. Choose a provider that offers reliable after-sales service, including training, troubleshooting, and spare parts availability.

6. Making the Right Choice: Evaluating Your Needs

Selecting the best filling machine requires a comprehensive analysis of your production goals, industry requirements, and budget constraints. By carefully evaluating these factors, you can make a decision that aligns with your business objectives and sets you up for success.

Conclusion

The search for the best Eye Drop Filling Machinesin China leads us to a landscape brimming with innovation and expertise. From accuracy-focused solutions to customer-centric approaches, the top providers mentioned in this article offer a range of choices for businesses aiming to elevate their manufacturing processes. As you embark on the journey of finding the perfect filling machine, remember to consider your unique needs and prioritize factors that contribute to seamless production and exceptional product quality.

FAQs (Frequently Asked Questions)

- Q: How do I determine the right production capacity for my filling machine needs?

- A: Assess your average production volume and growth projections to select a capacity that accommodates current and future demands.

- Q: What industries can benefit the most from precise filling machines?

- A: Industries such as pharmaceuticals, chemicals, and specialty foods, where accurate measurements are critical, can greatly benefit from precise filling machines.

- Q: Are these filling machines suitable for both liquid and solid products?

- A: Yes, many modern filling machines are designed to handle a wide range of products, including liquids, powders, and solids.

- Q: How can I ensure the filling machine integrates seamlessly into my existing production line?

- A: Prioritize machines that offer compatibility with your current setup and provide user-friendly interfaces for easy integration.

- Q: What should I consider when budgeting for a filling machine investment?

- A: In addition to the upfront cost, factor in long-term savings from increased efficiency, reduced labor, and improved product quality.