What is the Use of Emulsifier Machine? A Guide to Efficient Emulsification

In the world of modern manufacturing and food processing, emulsification plays a pivotal role in creating products with desirable textures, consistencies, and qualities. One of the key tools in achieving effective emulsification is the emulsifier machine. In this article, we will delve into the fascinating world of emulsification and explore the various applications and benefits of emulsifier machines.

Introduction to Emulsification

Emulsification is a process that involves the uniform dispersion of two immiscible liquids, typically oil, and water, into a stable emulsion. This process is widely utilized in various industries to create products with desired properties, such as smooth textures, consistent flavors, and proper blending of ingredients.

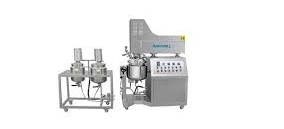

What is an Emulsifier Machine?

An emulsifier machine is a sophisticated equipment designed to facilitate the emulsification process. It is engineered to break down the molecules of two immiscible liquids, allowing them to mix evenly and form a stable emulsion. Emulsifier machines are essential tools in industries where precise and efficient blending is crucial.

How Does an Emulsifier Machine Work?

Emulsifier machines operate on the principle of high shear force. They utilize mechanical energy to create intense turbulence within the liquid mixture, causing the formation of tiny droplets. These droplets then collide and merge, eventually forming a uniform emulsion. The machine’s design and operating parameters play a crucial role in achieving optimal emulsification results.

Types of Emulsifier Machines

Homogenizers

Homogenizers are one of the most commonly used emulsifier machines. They work by forcing the liquid mixture through a narrow channel at high pressure, effectively breaking down larger droplets and ensuring uniform emulsion.

Ultrasonic Emulsifiers

Ultrasonic emulsifiers utilize ultrasonic waves to create micro-turbulence within the liquid mixture. This method is highly efficient for emulsifying heat-sensitive substances.

High-Pressure Emulsifiers

High-pressure emulsifiers subject the liquid mixture to extremely high pressures, causing intense agitation and emulsion formation. They are often used in industrial settings for large-scale production.

Industries Benefiting from Emulsifier Machines

Food and Beverage

The food and beverage industry extensively employs emulsifier machines to create products like sauces, dressings, mayonnaise, and dairy products. These machines ensure consistent textures and prevent separation of ingredients.

Cosmetics and Personal Care

Emulsifier machines are vital in cosmetics and personal care product manufacturing, helping to create lotions, creams, and other formulations that require uniform blending of oil and water.

Pharmaceuticals

In the pharmaceutical industry, emulsifier machines are used to produce pharmaceutical creams, ointments, and suspensions, ensuring even distribution of active ingredients.

Chemical Manufacturing

Chemical processes often require emulsification for producing paints, coatings, and various chemical compounds, where emulsifier machines play a critical role.

Advantages of Emulsifier Machines

Improved Product Stability

Emulsifier machines contribute to product stability by preventing phase separation and ensuring a homogeneous mixture. This leads to products with consistent quality and longer shelf life.

Enhanced Texture and Consistency

Products created using emulsifier machines exhibit improved textures and consistencies, enhancing the overall sensory experience for consumers.

Extended Shelf Life

Emulsification reduces the size of oil or fat droplets, slowing down spoilage processes and extending the shelf life of products.

Factors to Consider When Choosing an Emulsifier Machine

Viscosity and Flow Rate

The viscosity of the liquid mixture and the desired flow rate are crucial factors in selecting the appropriate emulsifier machine.

Processing Capacity

The production volume requirements dictate the size and capacity of the emulsifier machine needed.

Emulsification Method

Different emulsification methods may be more suitable for specific applications. Choosing the right method is essential for achieving desired results.

Maintenance and Care of Emulsifier Machines

Cleaning and Sanitization

Regular cleaning and sanitization procedures are essential to prevent contamination and ensure the longevity of the emulsifier machine.

Regular Maintenance Checks

Scheduled maintenance checks help identify and address potential issues, ensuring uninterrupted operation and optimal performance.

Common Challenges and How to Overcome Them

Phase Separation

Phase separation can occur if the emulsion is not stable. Adjusting formulation and emulsification parameters can help overcome this challenge.

Clogging and Blockages

Blockages in the emulsifier machine can be prevented through proper filtration and regular equipment maintenance.

Conclusion

Emulsifier machinesare indispensable tools across various industries, revolutionizing how we create products requiring stable and uniform emulsions. From food and beverages to cosmetics and pharmaceuticals, these machines ensure consistent quality, enhanced textures, and extended shelf life. By understanding the principles of emulsification and selecting the right emulsifier machine, manufacturers can elevate their production processes to new heights.

FAQs

- What is emulsification? Emulsification is the process of mixing two immiscible liquids to form a stable emulsion.

- How does an emulsifier machine work? Emulsifier machines utilize high shear force to break down liquid molecules and create a uniform emulsion.

- What industries use emulsifier machines? Emulsifier machines find applications in food, cosmetics, pharmaceuticals, and chemical manufacturing industries.

- Are there different types of emulsifier machines? Yes, there are various types, including homogenizers, ultrasonic emulsifiers, and high-pressure emulsifiers.

- How do emulsifier machines improve product stability? Emulsifier machines prevent phase separation, leading to products with consistent quality and extended shelf life.