What is the Process of Paper Production

In our modern world, paper is an everyday essential used for various purposes, from communication to packaging. Have you ever wondered about the intricate process behind its creation? In this article, we’ll delve into the fascinating journey of paper production, from raw materials to the finished product. Let’s explore the step-by-step process that transforms simple fibres into the versatile paper we use daily.

Introduction

Paper Lamination Machine, a versatile material, has a history that dates back centuries. However, its production process has evolved significantly over time. The modern process of paper production is a sophisticated blend of science, technology, and creativity.

Raw Materials: The Foundation of Paper

Paper production begins with raw materials, primarily wood fibres obtained from trees. These fibres are carefully selected and harvested from sustainable sources to ensure minimal environmental impact.

Pulping: Breaking Down the Fibers

In the pulping phase, the wood fibres are separated from other components of the wood, such as lignin and hemicellulose. This can be done through mechanical or chemical processes, yielding a mixture known as pulp.

Cleaning and Refining: Achieving Purity

The pulp undergoes cleaning and refining to remove impurities and create a consistent fibre mixture. This refined pulp is then ready for the next stage.

Paper Formation: From Pulp to Sheet

The refined pulp is diluted with water to form a slurry, which is then poured onto a wire mesh. As the water drains, the fibres begin to bond, creating a paper web.

Pressing and Drying: Removing Excess Moisture

The paper web is pressed to remove excess water and then passed through heated rollers to further reduce moisture content. This step also enhances the paper’s smoothness and thickness.

Sizing: Enhancing Strength and Water Resistance

Sizing agents are added to the paper to enhance its strength and resistance to water and ink penetration. This step ensures that the paper maintains its integrity during use.

Coating: Adding Gloss and Finish

In some cases, paper may undergo a coating process to achieve specific qualities, such as gloss or improved printability. Coatings can also enhance the paper’s visual appeal.

Calendering: Smoothing the Surface

The paper may be passed through calendering machines, which exert pressure to smooth the paper’s surface and improve its texture.

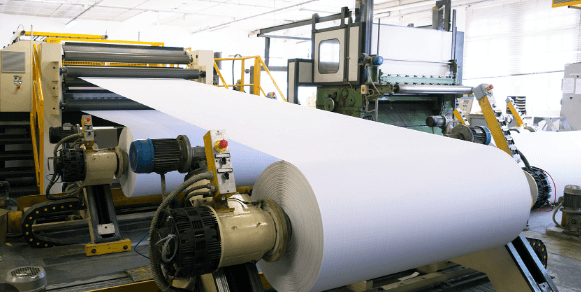

Cutting and Reeling: Forming Paper Rolls

Once the paper reaches the desired thickness, it’s cut into sheets or wound into rolls, depending on its intended use. Precision is crucial in this step to ensure uniformity.

Quality Control: Ensuring Consistency

Throughout the production process, rigorous quality checks are conducted to ensure that the paper meets the desired specifications. This includes monitoring factors like thickness, weight, and surface quality.

Recycling: A Sustainable Approach

In recent years, the paper industry has embraced recycling as a way to minimize waste and environmental impact. Recycling paper reduces the demand for fresh raw materials and conserves energy.

Innovations in Paper Production

Advancements in technology have led to innovations such as digital paper and sustainable paper products. These innovations continue to reshape the paper industry.

The Importance of Paper in the Digital Age

Despite the rise of digital communication, paper remains relevant in various sectors, such as packaging, printing, and art. Its tactile nature offers a unique experience that digital media cannot replicate.

Conclusion

The process of the Paper Lamination Machineis a remarkable journey that starts with simple fibres and culminates in a versatile material used worldwide. From the careful selection of raw materials to the intricate steps of refining, forming, and finishing, each stage contributes to the quality and usability of the final product. In a world undergoing rapid digital transformation, paper production continues to adapt and thrive, ensuring that this age-old material remains an integral part of our lives.

FAQs

- Is paper production harmful to the environment? Paper production can have environmental impacts, but sustainable practices and recycling efforts have significantly reduced its negative effects.

- What are the alternative materials to wood fibres for paper production? Besides wood fibres, paper can also be produced from alternative sources like agricultural residues and recycled paper.

- How does recycling paper benefit the environment? Recycling paper conserves resources, reduces waste in landfills, and minimizes the need for deforestation.

- Are digital documents more eco-friendly than paper? While digital documents save paper, they require energy and resources for electronic devices and data storage.

- What is the role of technology in modern paper production? Technology has improved efficiency, quality control, and sustainability in paper production through innovations in machinery and processes.