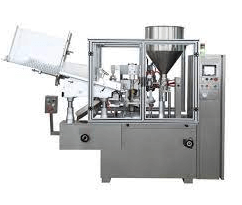

Automatic Filling Machines: Revolutionizing Production Efficiency

In today’s fast-paced manufacturing landscape, optimizing production processes is key to staying competitive. One of the most transformative innovations in this regard is the automatic filling machine. This article delves into the world of automatic filling machines, exploring their benefits, types, applications, and future prospects.

Introduction

In the realm of manufacturing, time is money, and efficiency reigns supreme. This has led to the rise of automatic filling machines, which have revolutionized the way products are packaged and distributed. Gone are the days of manual, labor-intensive filling processes; automatic filling machines have stepped in to streamline operations and optimize output.

The Evolution of Filling Processes

Filling processes have come a long way from their rudimentary beginnings. Historically, products were filled into containers by hand, a time-consuming and error-prone task. With the industrial revolution, semi-automatic filling machines emerged, partially alleviating the challenges of manual labor. However, it wasn’t until the advent of automatic filling machines that true transformation occurred.

How Automatic Filling Machines Work

Automatic Flow Meter Filling Machines operate on advanced technological principles that ensure consistent and efficient product filling. These machines are equipped with sensors, actuators, and control systems that enable them to dispense precise amounts of products into containers while maintaining a high production rate.

Types of Automatic Filling Machines

Liquid Filling Machines

Liquid filling machines are designed to handle a wide range of liquids, from water to viscous substances. They use various methods such as gravity, piston, or pressure filling to accurately dispense liquids into containers.

Powder Filling Machines

Powder-filling machines excel at filling powdered or granulated products. Auger-based mechanisms are commonly used to measure and dispense the powder with precision.

Volumetric Filling Machines

Volumetric filling machines work by filling a predetermined volume of product into containers. They are often used for liquids and viscous products.

Weight-Based Filling Machines

Weight-based filling machines measure the product’s weight as it’s being dispensed, ensuring accurate filling by adjusting for variations in density.

Advantages of Automatic Filling Machines

Enhanced Efficiency and Speed

Automatic filling machines drastically reduce production time compared to manual methods. They can consistently fill containers at a high rate, boosting overall output.

Precision and Accuracy

Precision is paramount in manufacturing, especially for industries like pharmaceuticals. Automatic filling machines ensure accurate filling, reducing the risk of underfilled or overfilled products.

Reduced Product Waste

By minimizing spillage and ensuring precise filling, automatic filling machines contribute to reduced product waste, leading to cost savings and environmental benefits.

Improved Safety

Manual filling processes can pose safety hazards for workers. Automatic filling machines enhance safety by minimizing human involvement in potentially risky tasks.

Applications Across Industries

Automatic filling machines find applications in various industries, including:

Food and Beverage

From sauces to beverages, automatic filling machines ensure consistent portioning and packaging, maintaining product quality and reducing labor costs.

Pharmaceuticals

In the pharmaceutical industry, precision and hygiene are paramount. Automatic filling machines meet stringent requirements for accurate dosing and contamination control.

Cosmetics and Personal Care

Cosmetic products require careful filling to maintain their integrity. Automatic filling machines handle a wide range of viscosities, ensuring seamless packaging.

Chemicals and Cleaning Products

The chemical industry benefits from automatic filling machines to accurately dispense potentially hazardous substances, enhancing worker safety.

Considerations for Choosing the Right Automatic Filling Machine

Selecting the appropriate automatic filling machine involves several factors:

Production Volume

Consider the production volume to ensure the chosen machine can meet your output requirements efficiently.

Type of Product

Different products have varying viscosity and handling characteristics. Choose a machine designed to handle your specific product type.

Filling Consistency

For industries where uniform filling is critical, opt for a machine that offers consistent and repeatable results.

Space and Layout

Evaluate the available space in your facility and choose a machine that fits seamlessly into your layout.

The Future of Automatic Filling Machines

As technology continues to advance, so do automatic filling machines:

Integration with Industry 4.0

Automatic filling machines are becoming part of the smart factory ecosystem, enabling remote monitoring, predictive maintenance, and data-driven optimizations.

Sustainability Initiatives

The future will see an increased focus on sustainability. Automatic filling machines will likely incorporate eco-friendly features, reducing energy consumption and waste.

Conclusion

Automatic Flow Meter Filling Machineshave undoubtedly reshaped the manufacturing landscape, optimizing processes and enhancing product quality. As industries continue to evolve, these machines will play a pivotal role in achieving efficiency, precision, and sustainability.

FAQs

- Q: Are automatic filling machines suitable for small-scale production? A: Yes, there are automatic filling machines designed to cater to small-scale production needs.

- Q: Can automatic filling machines handle products with particulate matter? A: Yes, certain models can handle products with particulates using specialized mechanisms.

- Q: How do automatic filling machines contribute to reduced product waste? A: Automatic filling machines dispense precise amounts, minimizing spillage and overfilling, thus reducing product waste.

- Q: Are automatic filling machines customizable for unique product requirements? A: Many automatic filling machines can be tailored to accommodate specific product characteristics and filling needs.

- Q: What maintenance is required for automatic filling machines? A: Regular cleaning, calibration, and routine maintenance are essential to ensure optimal performance and longevity.